- #Radial load calculator mobile equipment how to

- #Radial load calculator mobile equipment pdf

- #Radial load calculator mobile equipment manual

On an inclined conveyor, it is usually in the vicinity of the loading zone. Next it is important to calculate T2 sag (slack side tension required to prevent belt sag.) Sag is a phenomenon which can occur at the point of minimum tension in the carrying strand of a conveyor belt.

#Radial load calculator mobile equipment manual

The wrap factor can be as small as 0.08 for dual drive systems with rubber-lagged drive pulleys, an automatic take-up, and 420° of wrap angle, or as large as 1.2 for a single drive system, an unlagged pulley, manual take-up and 180° of belt wrap.

Required power equals effective tension times belt speed: The momentum component, Tam, is the tension required to accelerate the material on the belt from the initial velocity, as it hits the conveyor, to the terminal velocity, which is defined as the conveyor belt speed. The gravity components include: Tb, the tension required to lift or lower the conveyor belt, and Tm, the tension required to lift or lower material.

Some of the friction components are: Tbc, the tension required to overcome belt cleaner drag (The subject of another Rulmeca video) Tsb, the tension required overcome skirt board drag (The subject of another Rulmeca video) and Tyr, the tension required to overcome friction in the bearings of the return rollers as the empty belt travels over the return strand. These parameters enable the designer to calculate belt tension required to overcome: The CEMA Conveyor Design Manual provides this equation to calculate effective belt tension. We use historical nomenclature in this video and restrict the presentation to conveyors with standard loading conditions and continuous material flow. These methods include “historical”, “basic”, and “universal” methods. They are beyond the scope of this short video. The 5th, 6th, and 7th editions of the Conveyor Equipment Manufacturers’ Association Belt Conveyor Design Manual includes several methods to calculate the belt tension required to move bulk materials on a conveyor belt.

#Radial load calculator mobile equipment how to

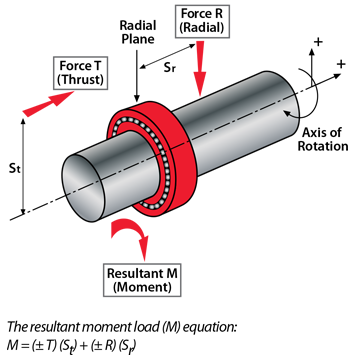

It explains basic principles involved in calculating belt tensions introduces key terms, such as effective tension, slack side tension, and total tension and serves as an introduction to our advanced tutorial on how to switch a single drive conveyor system to a dual drive conveyor system, to solve tension-related problems.Ĭommon components on a typical bulk handling belt conveyor include head pulley, snub pulley, flat belt, tail pulley, carrying idlers, return idlers, belt plow, counterweighted take-up, belt cleaner, loading skirts, hopper feeder, and slider bed. This tutorial is for bulk handling conveyor belt engineers and technicians challenged with designing a new conveyor system and conveyor operators confronted with belt tension related problems, such as belt slip, belt sag, or excessive radial load. The program not only determines required power, but also displays all Motorized Pulleys available (for 60 Hz power supply), and plots dimensional information to scale.

#Radial load calculator mobile equipment pdf

(free online cloud-based program, CEMA 7 version, part of RCS, Rulmeca Calculation System) Rulmeca Corporation assists conveyor designers and technicians with bulk handling conveyor belt pull and power calculations in four ways:

0 kommentar(er)

0 kommentar(er)